Supplementary protection certificates (SPCs) are an intellectual property right that serve as an extension to a patent right. SPC tools and procedures can help you monitor process behavior, discover issues in internal systems, and find solutions for production issues. Statistical process control (SPC) is defined as the use of statistical techniques to control a process or production method. SPC charts are constructed by plotting data (we suggest a minimum of 25 data points or more ideally) in time order, calculating and displaying the average (the mean) and some data comparisons known as the upper and lower control limits as lines. Understanding this variation is the first step towards quality improvement. These techniques enable the user to identify variation within their process.

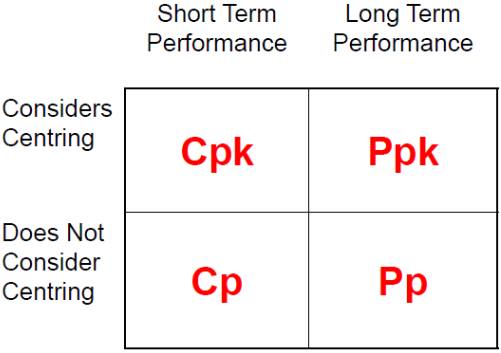

Statistical Process Control ( SPC) techniques, when applied to measurement data, can be used to highlight areas that would benefit from further investigation. Your Statistical process control chart is ready.This is what your final chart will look like.Click on Insert tab, click on Line Chart and then Click on Line.Select cell C1 and type "Mean (CL)" in it.Click on the Formula tab, click on More Function select Statistical and then STDEV.How do you use Cp and Cpk? Although statistical process control ( SPC) charts can reveal whether a process is stable, they do not indicate whether the process is capable of producing acceptable output-and whether the process is performing to potential capability.

0 kommentar(er)

0 kommentar(er)